Table of Contents

Toggle

What is an RFID System and How Does It Work

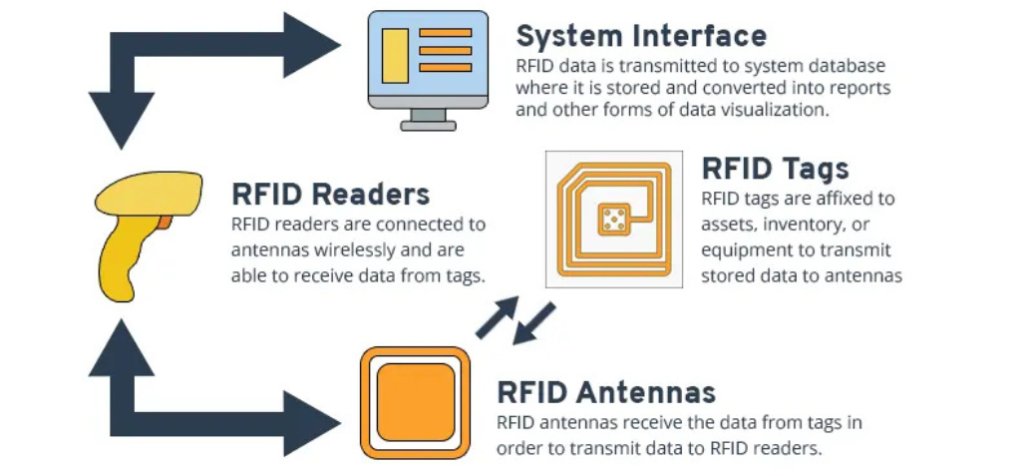

RFID Systems, which stand for Radio Frequency Identification, are a technology that uses radio waves to track and identify objects automatically. These systems have become increasingly popular in industries where speed, efficiency, and accuracy are critical. An RFID system consists of three main components: RFID tags, RFID readers, and antennas.

RFID tags are small devices attached to items or products that store information like product type, ID, and location. When an RFID tag comes into the RFID reader’s range, the reader collects the data from the tag. The antennas help enhance the communication between the tags and the readers, allowing businesses to track items accurately and in real time.

The great advantage of RFID Systems is that they can track multiple items at once without the need for line-of-sight scanning, unlike traditional barcode systems.

Common Challenges in Manual Tracking and Inventory Management

Manual tracking methods, such as using spreadsheets or barcodes, often lead to errors, delays, and missing items. Businesses face issues like overstocking, understocking, misplaced inventory, and high labor costs. These challenges not only increase operational costs but also reduce customer satisfaction. RFID Systems offer a smart alternative to eliminate such inefficiencies by automating data capture and improving visibility. By providing real-time tracking and instant updates, RFID helps businesses make more informed decisions, reduce waste, and streamline operations. This leads to better resource management and a more efficient supply chain overall.

How RFID Solves Inventory and Tracking Problems

Real-Time Data: RFID Systems provide immediate data on asset location and status, ensuring up-to-date information.

No Line-of-Sight Required: Unlike barcodes, RFID does not need a direct line-of-sight to scan items, making it more efficient.

Multiple Items Scanned Simultaneously: RFID can read multiple items at once, speeding up inventory counts and reducing time spent.

Reduction in Human Error: By automating data capture, RFID minimizes mistakes common in manual tracking systems.

Instant Tracking of Stock Movements: RFID allows businesses to instantly track inventory as it moves through the supply chain.

Prevention of Theft: With RFID, businesses can monitor inventory closely, reducing the risk of theft or loss.

Proactive Inventory Management: RFID systems offer instant alerts for low stock or expired items, allowing businesses to restock and manage inventory efficiently.

Streamlined Operations: With RFID in place, businesses can improve supply chain efficiency and overall operational performance.

Cost Reduction: RFID helps reduce operational costs by automating processes and improving accuracy, leading to better resource management.

Key Components of an RFID System Explained

An RFID System is made up of RFID tags, RFID readers, and antennas. RFID tags come in two main types: passive (no battery) and active (battery-powered). Readers collect data from the tags and transmit it to a central database, while antennas help boost the signal range. Together, these components create a seamless system that allows businesses to track products, equipment, or even personnel.

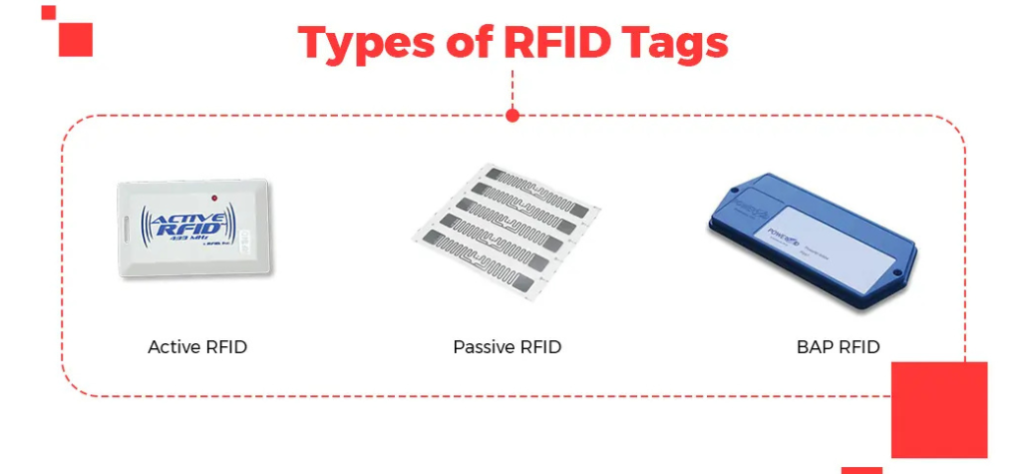

Types of RFID Tags and Their Applications

There are three main types of RFID tags that differ in how they transmit data and their power requirements. Each type is suited for different tracking applications.

- Passive RFID Tags: These are the most common and inexpensive type. They don’t have an internal power source and rely on the reader’s energy to transmit data. Passive tags are often used in retail and libraries for item tracking.

- Active RFID Tags: Active tags have their own power source (battery), which allows them to transmit data over much longer distances. These are used in industries where long-range tracking is required, such as tracking shipping containers or vehicles.

- Semi-Passive RFID Tags: These combine elements of both passive and active tags. They have a battery but only use it to power the tag’s internal circuit. They only transmit data when activated by an RFID reader. These tags are used in environments where moderate range and power are needed, such as in warehouses.

How RFID Enables Real-Time Inventory Visibility

One of the biggest benefits of RFID Systems is real-time visibility. Every item tagged with RFID can be tracked instantly as it moves through a warehouse, store, or delivery route. This helps businesses monitor stock levels, prevent shortages, and plan purchases more accurately. Real-time data also helps reduce shrinkage and increases inventory accuracy. Additionally, RFID allows businesses to make informed decisions quickly, reducing downtime and ensuring smoother operations. With RFID, businesses can access up-to-the-minute inventory information at any time, ensuring that they are always one step ahead in their supply chain management.

Security and Data Integrity in RFID Systems

RFID Systems are secure and can be encrypted to protect sensitive data. They help maintain data integrity by automatically recording item movements, reducing the risk of manual entry errors. Many RFID tags come with unique identifiers that cannot be duplicated, helping businesses prevent fraud and unauthorised access to valuable assets. Furthermore, RFID systems can be configured to restrict access to the data based on user roles, ensuring that only authorised personnel can view or modify critical information. This added layer of security ensures that businesses can rely on the system for accurate, safe, and protected asset tracking.

Cost-Benefit Analysis of Implementing RFID

Implementing RFID Systems may require an upfront investment, but the long-term savings are substantial. Businesses reduce labour costs, improve inventory accuracy, and avoid losses due to misplaced or stolen items. Over time, RFID Systems pay for themselves through increased efficiency and improved decision-making. Additionally, RFID helps reduce stockouts and overstocking, ensuring that businesses only keep the necessary inventory on hand. This leads to better resource management and fewer excess costs related to inventory. With real-time data, companies can also optimise their supply chain, resulting in faster delivery times and enhanced customer satisfaction.

Integrating RFID with ERP and Warehouse Management Systems

Modern RFID Systems can be easily integrated with ERP (Enterprise Resource Planning) and WMS (Warehouse Management Systems). This allows for seamless data flow between physical inventory and business software. It helps in automating restocking, generating reports, and making informed decisions based on accurate inventory data. Integration also improves real-time visibility into inventory levels, enabling businesses to optimise stock levels and reduce operational delays. By syncing RFID data with ERP and WMS, companies can enhance overall efficiency and accuracy in their supply chain management.

Future of RFID in Smart Inventory Management

The future of inventory management lies in smart technologies, and RFID Systems are leading the way. With advancements like cloud computing, AI, and IoT integration, RFID Systems are becoming more powerful. Businesses will soon be able to predict inventory trends, automate entire supply chains, and make smarter decisions using RFID data. These innovations will enable real-time, data-driven insights that improve forecasting accuracy and optimize warehouse operations. As RFID technology continues to evolve, businesses will achieve even greater levels of efficiency, reducing costs and improving overall supply chain resilience.

Industries Benefiting from RFID-Based Tracking Solutions

RFID Systems are used across multiple industries. In retail, they help in inventory control and theft prevention. In healthcare, RFID is used to track medical equipment and patient information. Logistics companies use it to manage fleets and shipments, while manufacturing firms track raw materials and production output. Virtually any industry can benefit from RFID’s ability to improve accuracy and efficiency. Agriculture and food industries also use RFID to monitor freshness, storage conditions, and traceability. As RFID technology becomes more affordable, its adoption is expected to grow even in smaller businesses and emerging markets.

Why Choose AIDC INDIA for Your RFID Needs

AIDC INDIA specialises in providing custom RFID Systems that suit the unique needs of every business. From consultation to installation and support, AIDC INDIA ensures you get a solution that delivers real results. With years of experience and a commitment to innovation, they are a trusted partner for RFID implementation. Their expert team stays updated with the latest RFID advancements to offer future-ready solutions. Plus, AIDC INDIA focuses on delivering cost-effective systems that maximise ROI and long-term performance for your business.

Case Study: Real-World Impact of RFID Implementation

A leading logistics company implemented RFID Systems with AIDC INDIA and reduced inventory errors by 90%. Stock counts that previously took 5 days now take just 3 hours. The business also saw a 30% increase in operational efficiency within 6 months. This case highlights how RFID Systems can transform business operations quickly and effectively. Employee workload was significantly reduced, allowing staff to focus on higher-value tasks. Additionally, customer satisfaction improved due to faster deliveries and more accurate order fulfilment.

Get Started with RFID Systems from AIDC INDIA

Ready to improve your tracking and inventory processes? RFID Systems from AIDC INDIA are designed to meet your specific challenges. Whether you’re in retail, logistics, or manufacturing, they offer end-to-end solutions to help your business grow smarter. Contact AIDC INDIA today for a free consultation and see how RFID can work for you. Their team of experts will guide you through every step—from planning to implementation and support. Start your journey toward smarter inventory control and increased operational efficiency with AIDC INDIA.

Transform your inventory management with AIDC INDIA’s smart RFID solutions.

Contact us today for a free consultation and take the first step toward real-time efficiency.